Czech Lager - The Bridge

I love Czech lager and I’ve yet to make a home brew lager.

Ever since watching the The Malt Miller’s ‘Brew With You’ episode on a Czech Lager with Radim Zvanovec, I’ve wanted to give it a go!

The video can be found here: https://www.youtube.com/watch?v=TMyMQfBFENs&t=1636s

An innovative single decoction lager.

Recipe

23L in the fermenter.

Grain

- 5kg - Weyermann Bohemian Pilsner

- 250g - Simpsons Dextrin Malt

Hops

- 44g - Möst

Hop Allocation

- 12g First Wort

- 12g Boil (30min)

- 20g Boil (15min)

Water

Should have been RO, but I broke the RO system the night before. Ended up using Tesco Ashbeck instead.

- 19.3L Mash

- 14.2L Sparge

Yeast

- 1 pkg ProMix - Boil (10 min)

- 2 pkg WHC Einstein

Hot Side

- Strike Temp: 69c

- Mash: 65c for 60min

- Decoction: ~7L at 20min of the mash. Immediately brought to the boil for 20min, then re-added to the mash for mash out.

- Mash Out: 75c for 10min

Cold Side

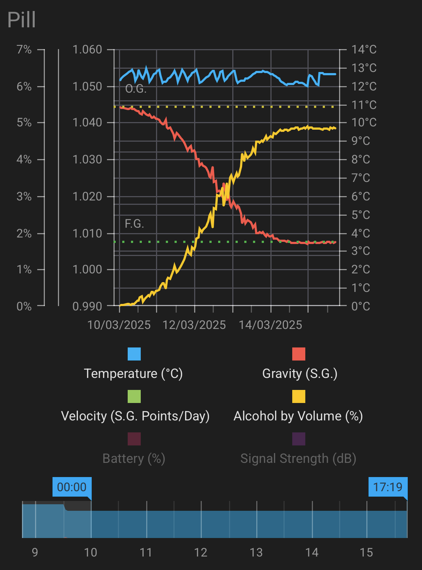

- Primary: 12 days @ 12c

- Diacetyl rest: 3 days @ 15c

- Cold crash: 4 days @ 4c (add ~10-15psi to prevent oxygen suck back)

Gravity

- OG: 1.041

- FG: 1.007

- ABV: 4.5%

- IBU: 28

Notes

Brew Day

I was really looking forward to this brew day. My first time making a lager.

Smooth start to the brew day, good recirculation.

The decoction mash step was simple too. I drew off ~7L and boiled it on an induction hob.

After returning the decoction to the mash, it bumps the temperature for the mash out, then onto the boil.

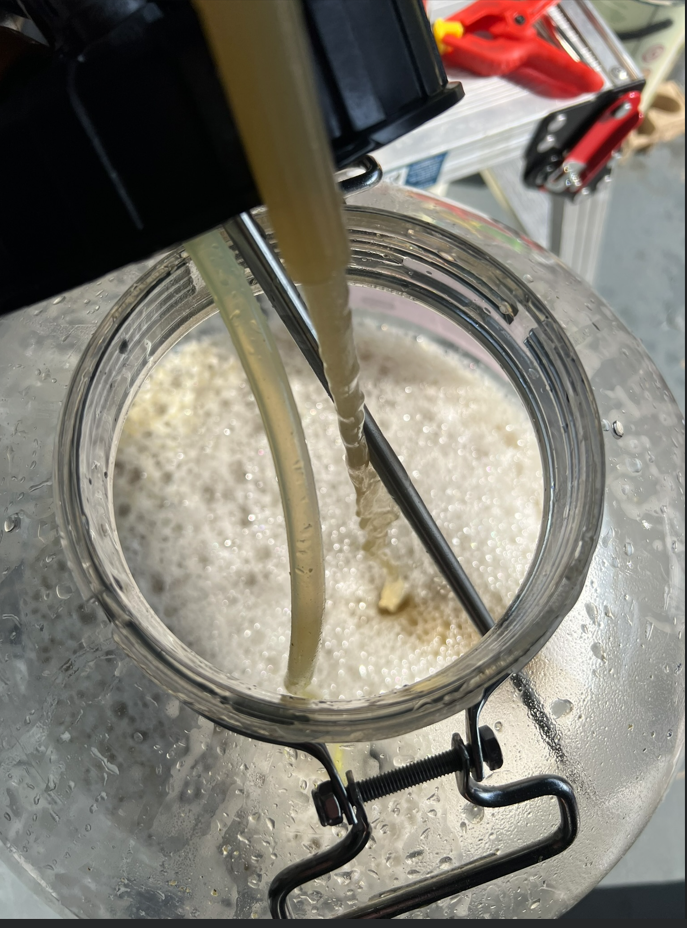

And finally the transfer to the fermenter. I didn’t make a starter for this brew, instead I used 2 pkgs of the Einstein yeast.

I managed to get a higher OG, 1.046 and it fishined up at 1.009.

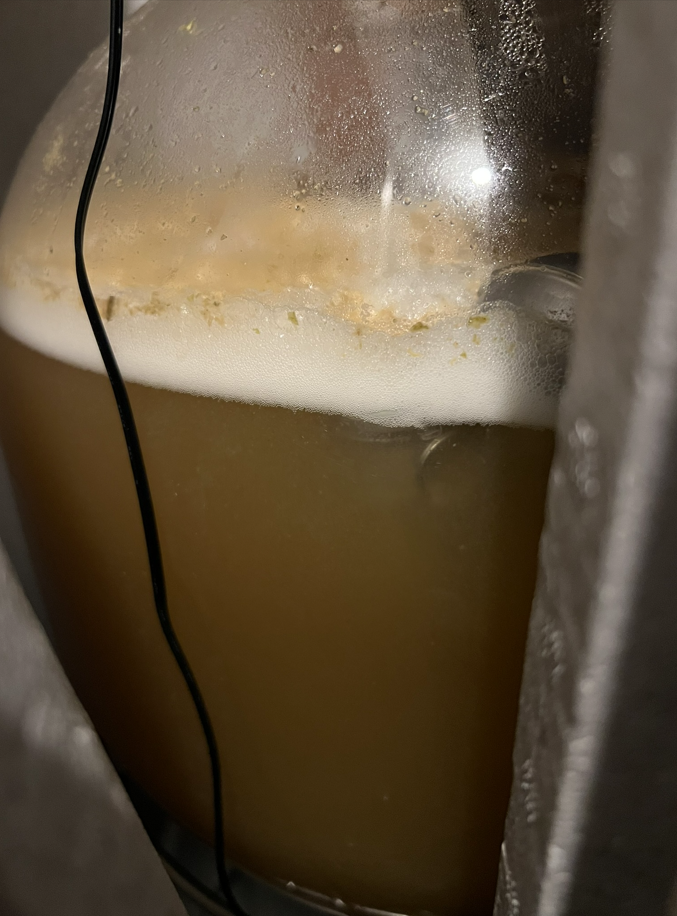

Steady fermentation and krausen:

Fermentation profile graphs:

Tasting

Ok, we have a problem!

After the transfer to the keg and cleaning up the fermenter - there was a strong apple/cidery smell. I knew this was acetaldehyde. I hoped for the best and that it would clean up in the keg. After a couple of weeks, it had improved but not fully.

After researching causes, these are some that I found

- Not enough yeast

- Poor yeast health

- Temperature problems

- Poor aeration

- Oxidation

- Infection

On reflection: I pitched enough yeast, added a yeast nutrient to the boil, full temperature control per recipe, aerated on the way in to the fermenter, ensured no oxygen contact and I throughly clean my equipment after/before every brew.

However, obviously I had hit one of the above problems. I reached out to Radim, he agreed on the acetaldehyde finding and we agreed extending the primary fermentation time to 20 days was the way forward. I decided to buy the kit again and do another batch.

It’s hard to take oxidation/infection as I take extra care on both of those points, but that is what I accepted it was.

Lessons learnt from this brew:

- Taste the beer during primary to check progress (I have a NukaTap Mini FC that makes this trivial)