First batch on the new brewery kit!

Now that I’ve setup my home brewery, these are the notes from my first brew day.

Recipe

20L in the fermenter

Grain

- 3.75kg / 58.6% - Maris Otter (Extra Pale)

- 1kg / 15.6% - Simpsons Golden Promise

- 1kg / 15.6% - Flaked Oats

- 650g / 10.2% - Carapils

Hops

- 3g Hallertau Magnum

- 140g Amarillo

- 140g Citra

- 140g Idaho #7

Hop Allocation

- 3g Hallertau Magnum: First Wort

- 15g each of Amarillo/Citra/Idaho #7: Boil (5min)

- 25g each of Amarillo/Citra/Idaho #7: Whirlpool: 20min @ 80c

- 100g each of Amarillo/Citra/Idaho #7: Dry Hop (~Day 7)

Water (Tap)

- 23L Mash

- 6.5L Sparge @ 80c

Water Treatment

- Calcium Chloride (5.5g Mash, 1.5g Sparge)

- Gypsum (2.4g Mash, 0.6g Sparge)

- Campden tablet

Yeast

- 1 pkg AEB Fermoale New-E

Hot Side

- Strike Temp: 73c

- Mash: 68c for 60min

- Boil: 30min

- Whirlpool: 20min @ 80c

Cold Side

- Primary: 5 days @ 20c

- Diacetyl rest: 5 days @ 21c

- Cool to 15c

- Dry hop, 3 day contact time

- Cold crash to 5c

Gravity/ABV

- OG: 1.076

- FG: 1.017

- ABV: 7.2%

- IBU: 32

Notes

Brew Day

Firstly, the mash was really thick, the recirculation wasn’t draining properly and I ended up with a few grains in the wort. I’ve ordered some rice hulls for the next batch to avoid that again!

I missed my pre-boil gravity due to this, but continued anyway - I wasn’t fussed with the end ABV droppping a bit.

The boil went fine, immersion chiller worked well getting down to whirlpool temp/80c. Kept some warm water for cleaning and had the mash basket/malt pipe cleaned up during the boil.

I whirlpool’d with a hop spider, I’ve seen mixed notes on this, but I kept the reciculation running, after the sticky mash I had, the last thing I wanted was a clogged pump!

Cooling and transferring went well too. All in all, really enjoyable first brew day on the new kit.

Fermentation

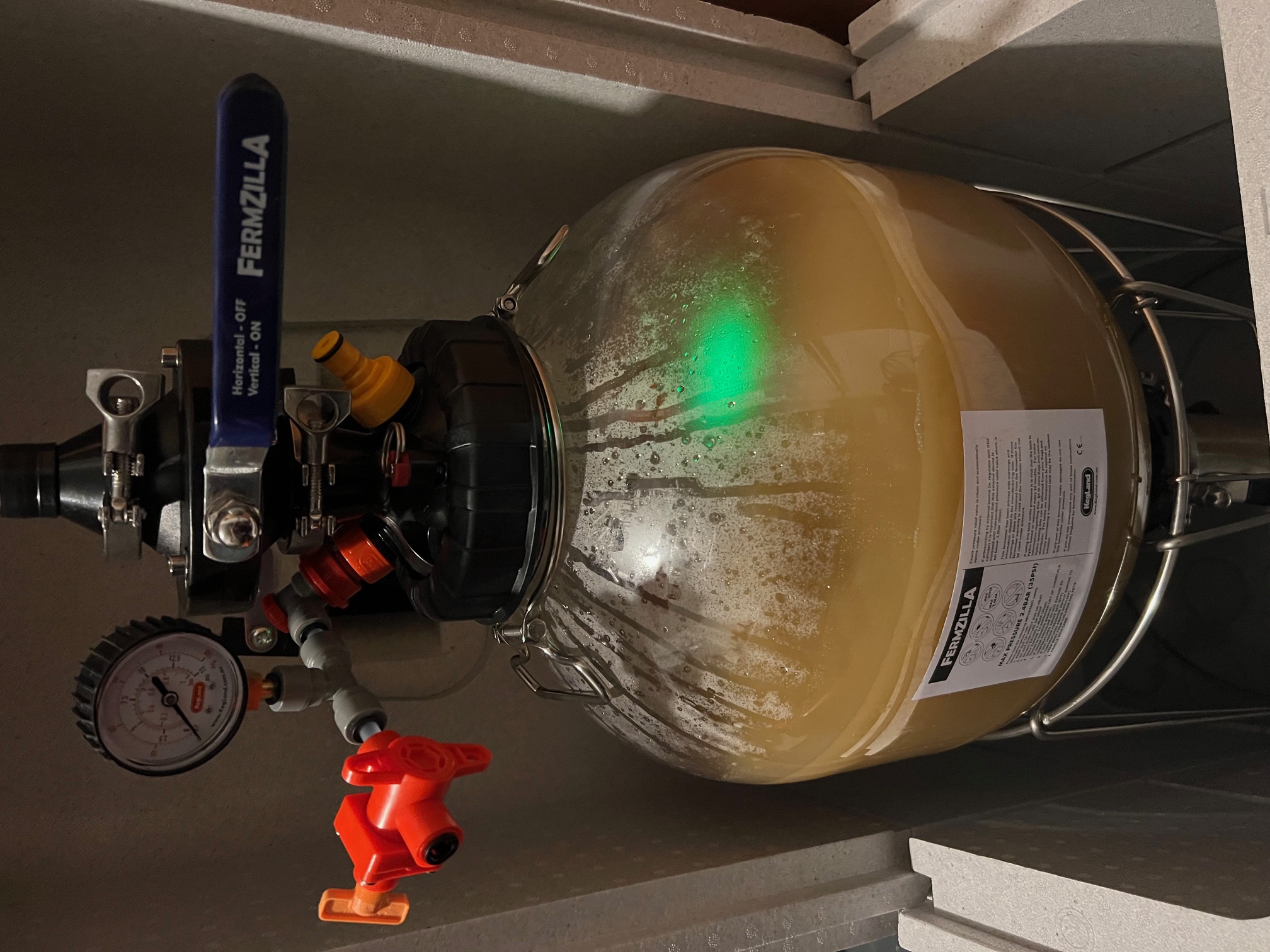

Fermentation started well, great experience with the RAPT Pill! I attached a spunding valve and left it open.

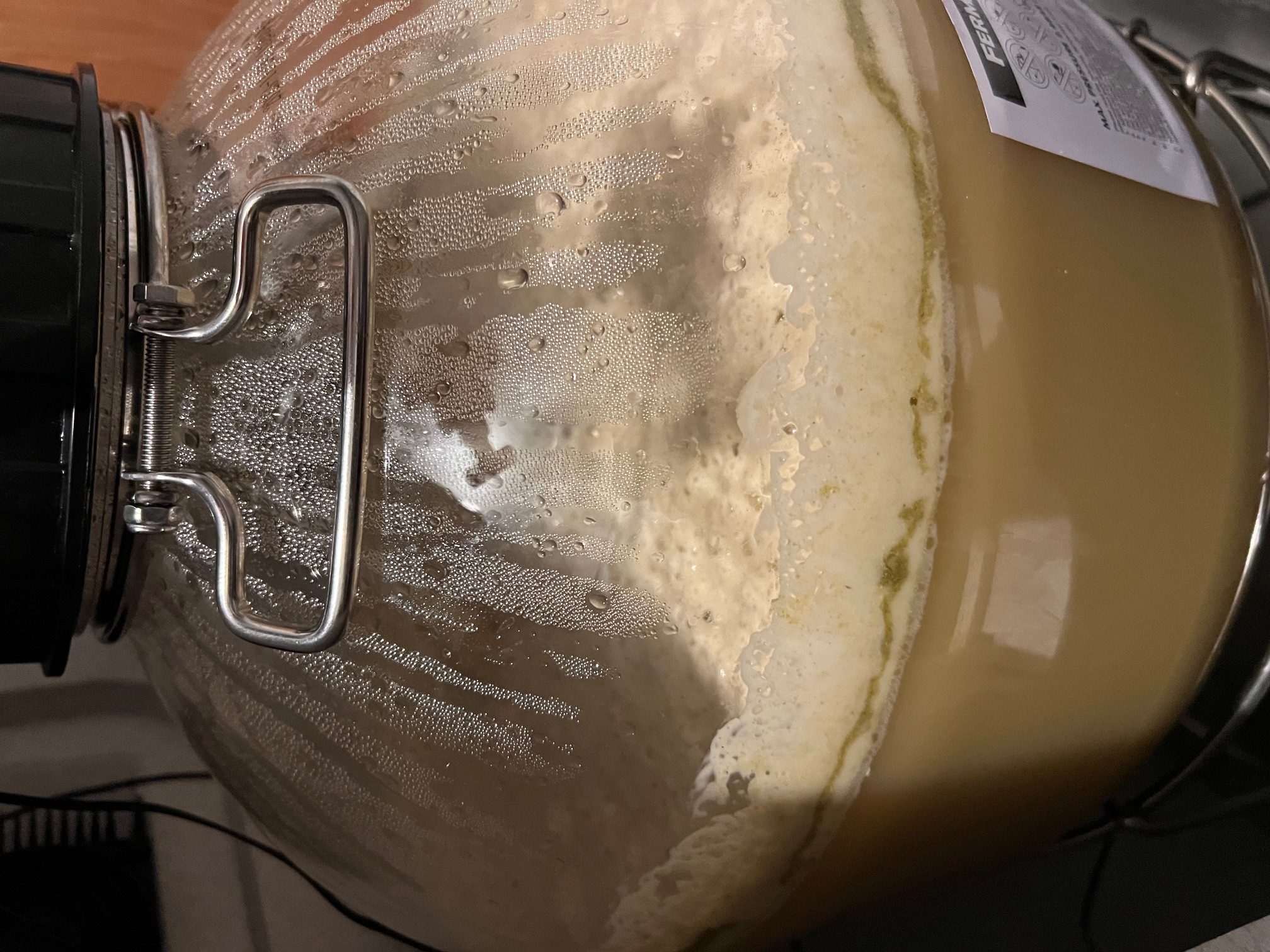

Couple of days in, I had a nice krausen!

Then it came to the dry hop - the hop bong is quality. I closed the spunding valve before the dry hop to build a small amount of CO2, I kept an eye on this daily and adjusted. In reality, I should have waited until after. I really wanted to avoid oxygen ingress during dry hop, even though the hop bong is effectively oxygen free.

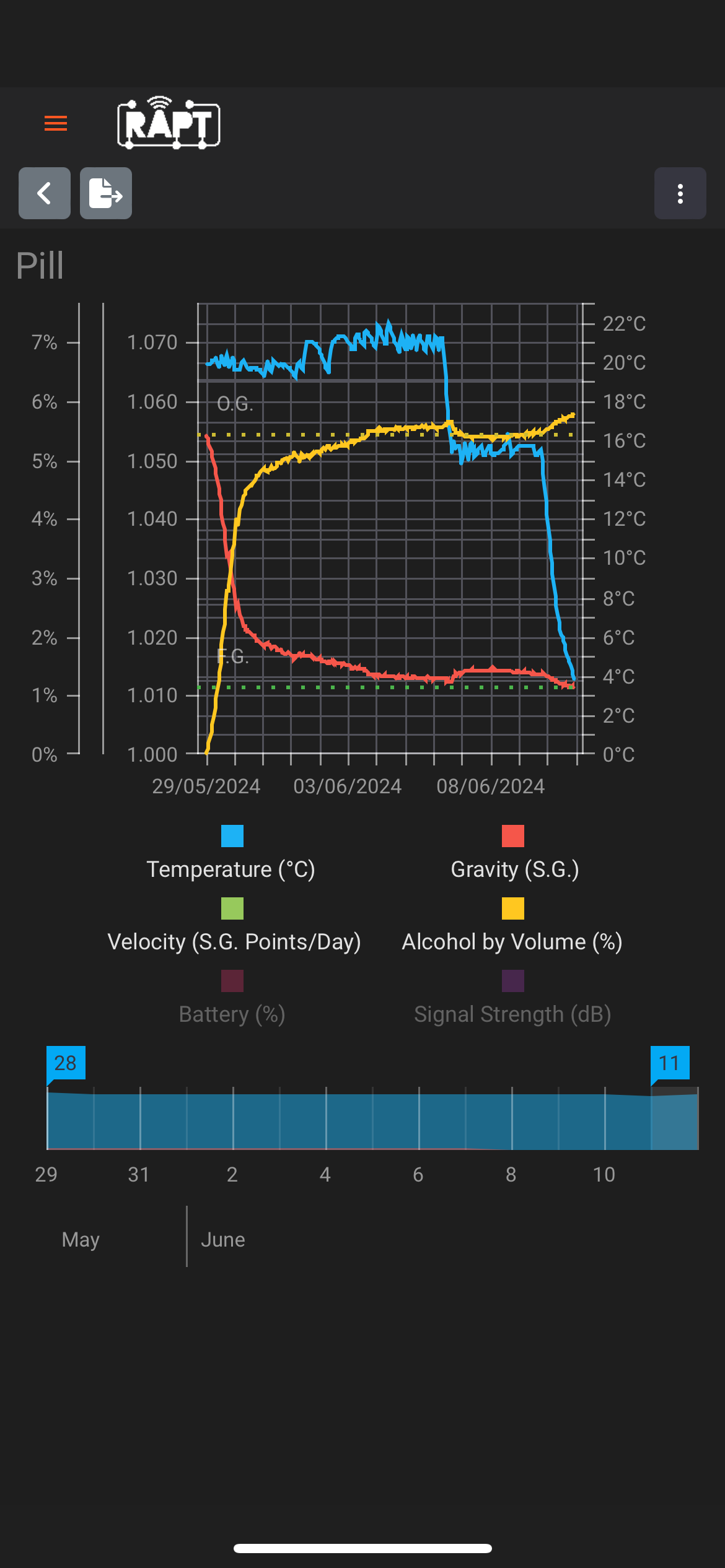

This is the fermentaton profile as captured by the Pill:

The blue dip you see a couple of days in was a mistake I made on the Ferminator, I set the temperature a little higher for D rest, but didn’t actually set. It ended up cooling to 20c again.

As mentioned earlier, I missed my OG considerably! 1.063 is what I recorded on the refractomter. Ended up at 6.2% rather than the target 7.2%.

I added pressure to ~10psi before the cold crash, to avoid any oxygen drawback.

After the cold crash, a closed transfer. I will buy another jumper and run this as a loop next time.

Tasting

I left it in the keg at ~5c for a few weeks. My SodaStream leaked which caused me a bit of a panic as it could have been leaking from the keg which could have meant a ruined batch, thankfully just one of the hoses a little loose.

As you can see, the carbonation isn’t tight enough at this point, but it was tasting good!

Served to friends a few weeks after this photo and it went down well! It had really balanced out by that point.

I was really happy with the result. Pushed the boat out a bit with the first batch, I probably should have done a cheaper/simplier recipe to start off with.

Looking forward to the next brew. I’ve got a reverse osmosis system on the way…!